|

We are extremely proud to report the completion of a large remodel and upgrade

project at Safeway's Bread Plant in Bellevue , Washington.

We met with Bread Plant Engineer, Keith Fenley and Refrigeration Contractor Nathan Roberts, owner of

Electromatic Refrigeration, several months

ago to discuss some cooling issues they were experiencing with their existing Chiller System.

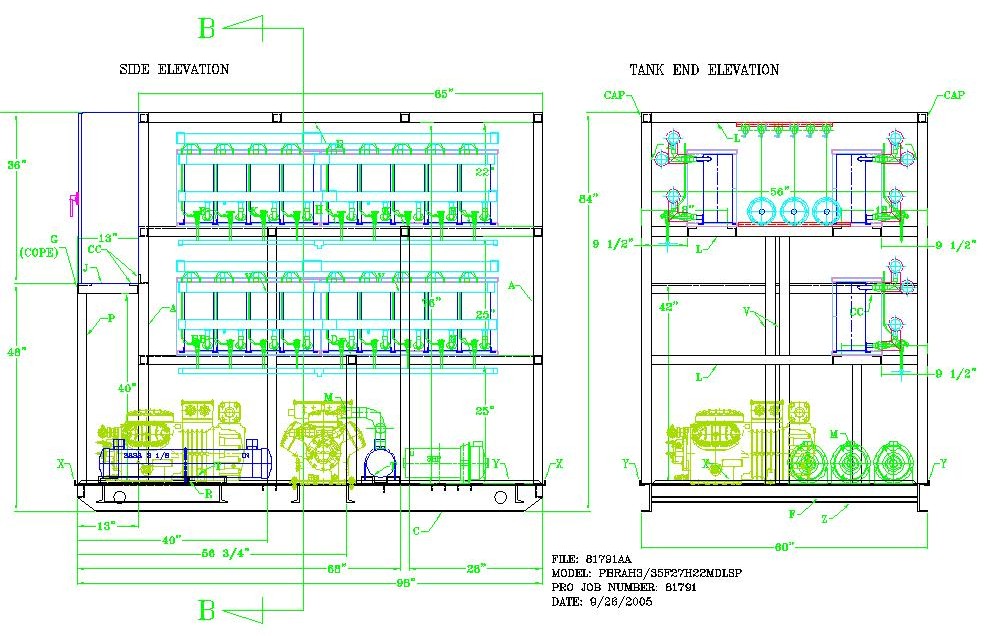

We identified some key weaknesses in their existing system (pictured above),

as well as some parts of the system that were working very well and could be incorporated into an upgraded system.

Collectively we designed a cooling system to fit their budget, their application, and the physical restrictions

of their mechanical room.

In the end we replaced their Dual 70 HP Screw Compressor System with a custom designed 105 HP System supplied

with 3 EA 35 HP Bitzer Compressors. From their existing system we utilized their glycol centrifugal pumps and

fiberglass chilled glycol storage tank. The retrofit required minimal piping changes to Safeway's existing

chilled water piping to the processing plant.

The new system also included the new CR110 Refrigeration Controller......

and high efficient Horizon Circuited Remote Air Cooled Condensers. (Nate Roberts pictured above)

Our biggest challenge was designing a system that could be installed without shutting down the customers production

line. Although it required almost round the clock coordination (and labor) to make the changeover happen, Nate and

his crew came through and had the equipment up and ready on Monday morning at the beginning of the new shift.

It is a real pleasure working with Keith (blue hair net) and his crew at the bakery

and also Nate Roberts (red hairnet) and his crew. We look forward to working with

both of them much more in the future! Great Job!

Our last report from Keith was very positive- Although only online for a couple weeks the system has performed

flawlessly, exceeding their expectations!!

|