PRO Unveils The World’s Largest Packaged CO₂ Chiller System Built for Dairy

Setting a new global benchmark for CO₂-based milk cooling technology

PRO Chiller Systems is proud to announce the unveiling of its most advanced and powerful CO₂-based chiller system to date at the upcoming World Dairy Expo in Madison, Wisconsin.

At the forefront of this innovation are two newly constructed 200 HP PROGreen Air-Cooled CO₂ Chillers, the largest packaged systems ever developed in the PROGreen series. Engineered to support one of the world’s most ambitious dairy operations, these chillers represent a significant leap forward in sustainable refrigeration for the dairy industry.

At the forefront of this innovation are two newly constructed 200 HP PROGreen Air-Cooled CO₂ Chillers, the largest packaged systems ever developed in the PROGreen series. Engineered to support one of the world’s most ambitious dairy operations, these chillers represent a significant leap forward in sustainable refrigeration for the dairy industry.

These next-generation systems are built for a forward-thinking VIP dairy customer who operates nearly 30 farms across the U.S. Their newest site, now under development in South Dakota, will be the largest dairy in the world to commit exclusively to natural refrigerant-based cooling and water heating. Designed to serve an initial herd of 25,000 cows, the facility is expected to double in scale in the near future.

“This is the biggest test yet for the PROGreen System in both scale and project scope,” shared PRO’s CEO, Jim VanderGiessen Jr. “Our team can’t wait to show the benefits that include not only cooling the farm’s milk more efficiently but also serving as the farm’s primary source for hot water.”

In addition to delivering powerful, energy-efficient cooling, these chillers are equipped with advanced heat recovery capabilities. These features allow the systems to capture and repurpose waste heat to generate hot water, meeting the farm’s high demand for sanitation, cleaning, and other daily operations. By using reclaimed thermal energy, the farm will not only reduce its reliance on traditional water heating methods but also cut operational costs and carbon emissions, reinforcing PRO’s position as a leader in sustainable dairy production.

To prepare for deployment, PRO recently hosted an intensive two-day technical training course with the farm’s operations team and more than a dozen industry technicians in Mocksville, North Carolina. The program gave attendees a hands-on introduction to the technology, providing the opportunity to engage directly with the systems before shipment and preparing them for real-world operation and maintenance. PRO has two additional training courses scheduled in Mocksville in 2025.

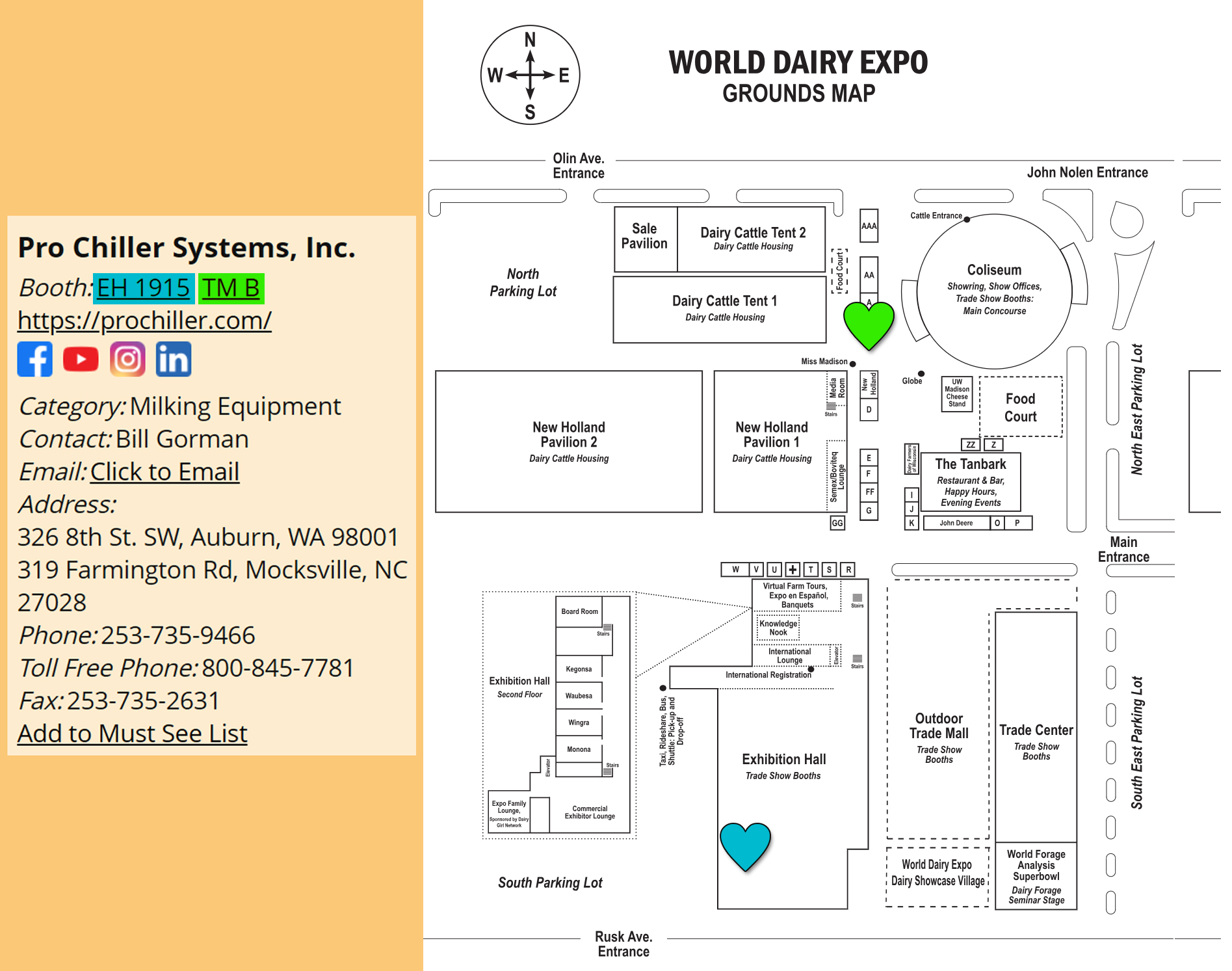

One of the two chiller units will soon be en route to the World Dairy Expo, where it will be proudly displayed across from the main entrance to the Coliseum. Attendees will be able to view the cutting-edge design up close and learn more about how PROGreen technology is shaping the future of energy-efficient, environmentally friendly cooling for the dairy sector.

One of the two chiller units will soon be en route to the World Dairy Expo, where it will be proudly displayed across from the main entrance to the Coliseum. Attendees will be able to view the cutting-edge design up close and learn more about how PROGreen technology is shaping the future of energy-efficient, environmentally friendly cooling for the dairy sector.

The PRO Refrigeration team (with the Dairy Farmer) will be on-site throughout the event to share insights on system capabilities, performance metrics, and the transition to natural refrigerants in large-scale agricultural settings.

👉 Visit us at the World Dairy Expo – Outside across from the Coliseum in Space B,

and inside the main Exhibition Hall in Booth #1915.